Plastic strapping of produce, fruit,veg, flowers, etc

.. frequently takes the form of filled plastic trays stacked many layers high and secured with three horizontal straps applied by hand at the bottom, mid point and top of the stack. The process of applying the straps is slow as the operator has to pull strap from the reel, walk around the pallet pick up a buckle or strapping tool, apply some tension, insert corner boards, apply final tension - keeping the strap horizontal - and finally sealing it off.

By normal production standards not only is the strapping process very slow but extremely expensive - a point frequently overlooked as it's generally only the cost of the strapping that is focussed on, and yet simple calculations quickly show the true cost of this style of operation.

Assume 50 pallets a day are strapped - each with three straps - and the time taken per pallet is averaging 3 minutes. Assume also that the labour rate is say 13 pence a minute. It follows that the labour cost for each pallet will be 39 pence.

Annual cost could then be calculated as:

50 pallets x 5 days x 50 weeks x £0.39 = £4,875 p.a. But the cost could be halved, together with the time taken with low cost equipment that offered payback in approx 6 months.

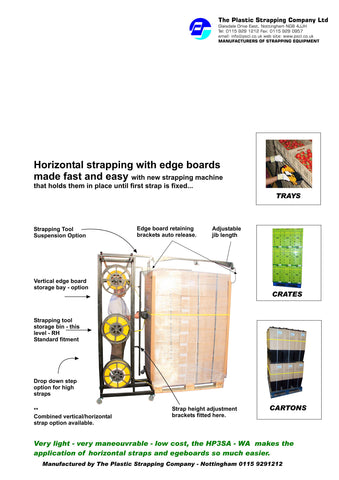

The sketch below shows the type of maintenance free equipment that would meet these objectives.

For more information and advice email info@pscl.co.uk or call 0115 9291212