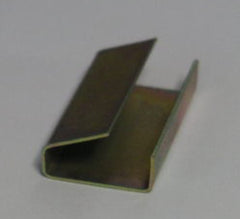

Strapping Clips - Standard & Heavy Duty

Plastic Strapping Clips and Seals - The difference

The difference in performance between standard and heavy duty plastic strapping clips or seals is often mis-understood both by users and even some packaging companies/catalogues that supply them, as the standard clips are often described as suitable for medium and heavy duty applications, and supplied with plastic strapping strapping suited to those type of applications i.e break strengths of 190 kgs and more, yet the fact remains that these seals will only hold 60 - 100 kgs before the they allow strapping to slip through. They are in fact only suited to cartons and not palletised loads. It is not unusual for users to tug on the straps after applying it to a pallet to assure themseves it is secure, but this is a false test as it does not even begin to approach the shock loading that that would be applied to the strap in the event of accident.

The reason for this is that strapping crimpers or sealers generally have three sets of sealing jaws and to get all three sets of jaws onto a seal to produce three 'crimps' requires a seal that is 32mm approx long. The standard clip sold for plastic strapping is only 25mm long so only two, instead of three sealing jaws can be located on the length of the seal reducing it's efficiency by 33%.

Other factors affecting the seal performance are the quality and thickness of steel used to manufacture them. It is often the case that the strip steel used is that that has been slit of the edges of the large rolls of sheet steel as they come from the rolling mills so both quality and thickness may vary from time to time unless an assured source is used.